Fanuc 0i Parameter Manual

1785 Parameter for determining an allowable acceleration when the feedrate is set by acceleration Data type Word-axis Unit of data msec Valid data range 0 to 32767 This parameter sets the time required to attain the maximum cutting feedrate to determine the allowable acceleration when the feedrate is determined by acceleration in look-ahead control (multiple blocks are read in advance) mode. The maximum cutting feedrate and the data set in this parameter are used to determine the allowable acceleration. As the maximum cutting feedrate parameter, parameter No.

1432 (maximum cutting feedrate in look-ahead control (multiple blocks are read in advance) mode) is used. Computer Numerical Control ProductsSeries 0i—Model AParameter ManualJune 2000GFZ-63510EN/01. GFL-001Warnings, Cautions, and Notes as Used in this PublicationWarningWarning notices are used in this publication to emphasize that hazardous voltages, curren. B-63510EN/01 PREFACERelated ManualsThe mode covered by this manual, and their abbreviations are:Product NameAbbreviationsFANUC Series 0/-TA0/-TASeries 0/FANUC. B-63510EN/01PREFACE. DISPLAYING PARAMETERS.

Fanuc Oi Parameter Manual

Table of Contents B-63510EN/014.26 PARAMETERS OF AUTOMATIC TOOL COMPENSATION (T SERIES) ANDAUTOMATIC TOOL LENGTH COMPENSATION (M SERIES). B-63510EN/01 1. DISPLAYING PARAMETERS1Follow the procedure below to display parameters.(1) Press the function key on the MDI as many times asrequired,.

2. SETTING PARAMETERS FROM MDI B-63510EN/01Follow the procedure below to set parameters.(1) Place the NC in the MDI mode or the emergency stop state.(2) Follow. B-63510EN/01 2.

SETTING PARAMETERS FROM MDIExample 12000 INPUTData can be entered continuously for parameters, starting at the selected parameter, by separa. 3. INPUTTING AND OUTPUTTING PARAMETERS THROUGHTHE READER/PUNCHER INTERFACEB-63510EN/01INPUTTING AND OUTPUTTING PARAMETERS THROUGH THE READER/PUNCHER INTERFACE3T.

B-63510EN/013. INPUTTING AND OUTPUTTING PARAMETERS THROUGHTHE READER/PUNCHER INTERFACE(1) Select the EDIT mode or set to Emergency stop.3.1OUTPUTTING PARAMETERS. 3. INPUTTING AND OUTPUTTING PARAMETERS THROUGHTHE READER/PUNCHER INTERFACE B-63510EN/013. INPUTTING AND OUTPUTTING PARAMETERS THROUGHTHE READER/PUNCHER INTERFAC.

B-63510EN/01 4. DESCRIPTION OF PARAMETERSParameters are classified by data type as follows:Table 4 Data Types and Valid Data Ranges of Parameters1 For the bit t. 4.

DESCRIPTION OF PARAMETERS B-63510EN/011 The bits left blank in 4. DESCRIPTION OF PARAMETERSand parameter numbers that appear on the display but arenot found. B-63510EN/01 4. DESCRIPTION OF PARAMETERS#7#6#5#4#3#2#1#00000SEQINIISOTVCSetting entry is acceptable.Data type BitTVC TV check0: Not performed1: PerformedIS.

4. DESCRIPTION OF PARAMETERS B-63510EN/01#7 #6#5#4#3#2#1#0SJZSetting entry is acceptable.Data type BitSJZ Manual reference position si performed as follows:0. B-63510EN/01 4.

DESCRIPTION OF PARAMETERSNOTE1 An input/output device can also be selected using the setting screen. Usually, the setting screenis used.2 The sp. 4.

DESCRIPTION OF PARAMETERS B-63510EN/014. DESCRIPTION OF PARAMETERS B-63510EN/014.2PARAMETERS OFREADER/PUNCHERINTERFACE0020This section describes the paramete. B-63510EN/01 4. DESCRIPTION OF PARAMETERS#7#6#5#4#3#2#1#00100ENSIOPND3NCRCTVParameters Common to all ChannelsSetting entry is acceptable.Data type BitCTV: Cha.

4. DESCRIPTION OF PARAMETERS B-63510EN/014.2.2Parameters of Channel 1(I/O CHANNEL=0)#7#6#5#4#3#2#1#00101NFDASISB2Data type Bit typeSB2 The number of stop bits. B-63510EN/01 4. DESCRIPTION OF PARAMETERS4.2.3Parameters of Channel 1(I/O CHANNEL=1)#7#6#5#4#3#2#1#0NFDASISB2Data type BitThese parameters are used when I/O C. 4.

DESCRIPTION OF PARAMETERS B-63510EN/01#7#6#5#4#3#2#1#00960SPEPMNMD2MD1SLVData type BitSLV When the power mate CNC manager is selected, the screen displays:. B-63510EN/01 4. DESCRIPTION OF PARAMETERS#7#6#5#4#3#2#1#0INMWhen this parameter is set, the power must be turned off before operation is continued.Data type B.

4. DESCRIPTION OF PARAMETERS B-63510EN/01XIK When LRP, bit 1 of parameter No.

1401, is set to 0, namely, when positioning is performed using non-linear type pos. B-63510EN/01 4. DESCRIPTION OF PARAMETERSB-63510EN/01 4.

DESCRIPTION OF PARAMETERSNOTEThe state in which the reference position has not been established refers. 4. DESCRIPTION OF PARAMETERS B-63510EN/01ROTx, ROSx Setting linear or rotation axis.ROSxROTxMeaning00Linear axis(1) Inch/metric conversion is done.(2) All coord. B-63510EN/01 4. DESCRIPTION OF PARAMETERSB-63510EN/01 4. DESCRIPTION OF PARAMETERSRABx In the absolute commands, the axis rotates in the direction0: In which t.

4. DESCRIPTION OF PARAMETERS B-63510EN/01#7#6#5#4#3#2#1#0IDGxData type Bit axisIDGx The function for setting the reference position again, without dogs, is:0. B-63510EN/01 4. DESCRIPTION OF PARAMETERS1020Program axis name for each axisData type Byte axisSet the program axis name for each controlled axis, using one o. 4.

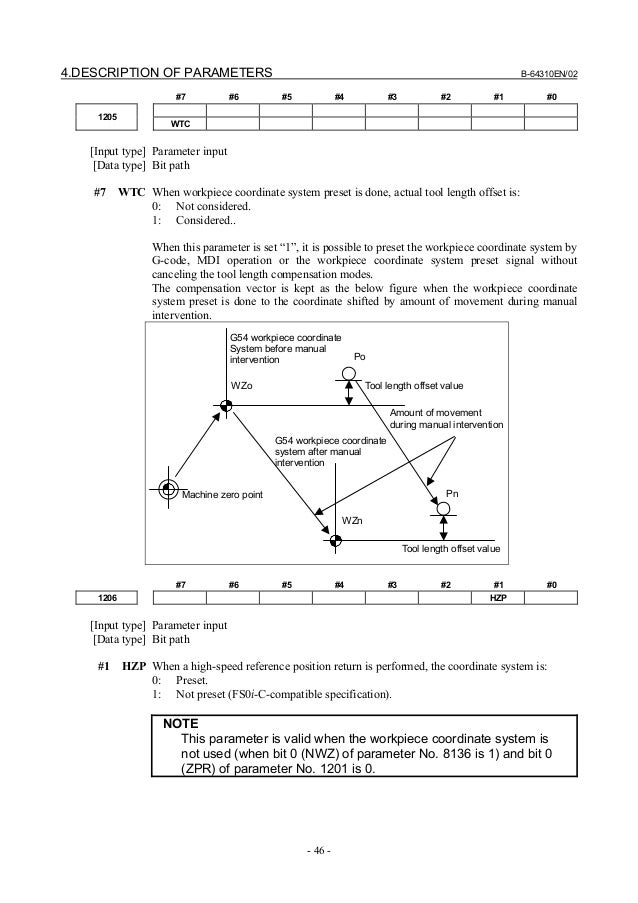

DESCRIPTION OF PARAMETERS B-63510EN/01Setting of each axis in the basic coordinate system1022NOTEData type Byte axisTo determine the following planes used. B-63510EN/01 4. DESCRIPTION OF PARAMETERS4.5#7 #6#5#4#3#2#1#0WZRAWKZCLAWKZCLPARAMETERS OF COORDINATESData type BitZCL Local coordinate system when the manual. 4. DESCRIPTION OF PARAMETERS B-63510EN/01RLC Local coordinate system is0: Not cancelled by reset1: Cancelled by resetG52 In local coordinate system setting (G.

B-63510EN/01 4. DESCRIPTION OF PARAMETERSValid data range -99999999 to 99999999The workpiece zero point offset values in workpiece coordinate systems 1 to 6 (. 4.

DESCRIPTION OF PARAMETERS B-63510EN/01Valid data range -99999999 to 99999999Set the coordinate values of the reference positions in the machine coordinate. B-63510EN/01 4. DESCRIPTION OF PARAMETERS#7 #6#5#4#3#2#1#0BFALZRRL3LMSOUTBFALZRLMSOUTOUT The area inside or outside of the stored stroke check 2 is set as an in. 4. DESCRIPTION OF PARAMETERS B-63510EN/01OT3x Whether stored stroke check 3 is checked for each axis is set.

0: Stored stroke check 3 is not checked.1: Stored s. B-63510EN/01 4.

DESCRIPTION OF PARAMETERSValid data range -99999999 to 99999999Set the coordinate values of stored stroke check 2 in the positive and negative. 4. DESCRIPTION OF PARAMETERS B-63510EN/014.

DESCRIPTION OF PARAMETERS B-63510EN/011326Coordinate value II of stored stroke check 1 in the positive direction on. B-63510EN/01 4. DESCRIPTION OF PARAMETERS#7 #6#5#4#3#2#1#0RDRTDRRF0JZRLRPRPDRDRTDRRF0LRPRPDPARAMETERS OF FEEDRATEData type BitRPD Manual rapid traverse during. 4. DESCRIPTION OF PARAMETERS B-63510EN/014. DESCRIPTION OF PARAMETERS B-63510EN/01#7 #6#5#4#3#2#1#0RTVMIFNOTEWhen this parameter is set, the power must be turne. B-63510EN/01 4.

DESCRIPTION OF PARAMETERS F8A Valid data range for an F command in feed-per-minute mode 0: Range specified with bit 0 (MIF) of para. 4. DESCRIPTION OF PARAMETERS B-63510EN/011410Dry run rateData type Word Unit of dataIncrement systemUnit of dataValid data rangeIS-BIS-CMillimeter machine1.

B-63510EN/01 4. DESCRIPTION OF PARAMETERSData type Word axis Unit of dataF0 rate of rapid traverse override for each axis1421Increment systemUnit of dataVal. 4. DESCRIPTION OF PARAMETERS B-63510EN/01(2) When JRV, bit 4 ofparameter No.1402, is set to 1 (feed per revolution) in T series, specify a jog feedarate (feed p. B-63510EN/01 4. DESCRIPTION OF PARAMETERS1427External deceleration rate of rapid traverse for each axisData type Word axis Unit of dataIncrement systemUnit. 4.

DESCRIPTION OF PARAMETERS B-63510EN/01reference position is set (when reference position return operation is performed using rapid traverse without decelerat. B-63510EN/01 4. DESCRIPTION OF PARAMETERS1432Maximum cutting feedrate for each axis in the look-ahead control modeData type 2-word axis Unit of data, valid r. 4. DESCRIPTION OF PARAMETERS B-63510EN/011451Feedrate for F1 digit command F11452Feedrate for F1 digit command F21453Feedrate for F1 digit command F31454Feedrat. B-63510EN/01 4. DESCRIPTION OF PARAMETERSB-63510EN/01 4.

DESCRIPTION OF PARAMETERS1460Upper limit of feedrate for the one-digit F code command (F1 to F4)1461Upp. 4. DESCRIPTION OF PARAMETERS B-63510EN/014.81601#7#6#5#4#3#2#1#0NCIRTOACDNCIRTOOVBData type BitPARAMETERS OF ACCELERATION/DECELERATIONCONTROLOVB Block overlap.

B-63510EN/01 4. DESCRIPTION OF PARAMETERS#7 #6#5#4#3#2#1#0COVLS2CSDCOVFWBData type BitFWB Cutting feed acceleration/deceleration before interpolation0: Type. 4. DESCRIPTION OF PARAMETERS B-63510EN/01#7 #6#5#4#3#2#1#0BELData type BitBEL In look-ahead control (multiple blocks are read in advance) mode:0: Linear acce. B-63510EN/01 4. DESCRIPTION OF PARAMETERSB-63510EN/01 4. DESCRIPTION OF PARAMETERS Rapid traverse feed rateTime.

4. DESCRIPTION OF PARAMETERS B-63510EN/014. DESCRIPTION OF PARAMETERS B-63510EN/011622Time constant of aceeleration/deceleration in cutting feed for each axisD. B-63510EN/01 4. DESCRIPTION OF PARAMETERSData type Word axis Unit of dataIncrement systemUnit of dataValid data rangeIS-BIS-CMillimeter machine1 mm/min6 to. 4. DESCRIPTION OF PARAMETERS B-63510EN/014.

DESCRIPTION OF PARAMETERS B-63510EN/011710Minimum deceleration ratio (MDR) of the inner circular cutting rate in aut. B-63510EN/01 4. DESCRIPTION OF PARAMETERSData type Unit of data1713Distance Le from the starting point in inner corner overrideWordIncrement systemIS-BIS-CU.

4. DESCRIPTION OF PARAMETERS B-63510EN/014.

DESCRIPTION OF PARAMETERS B-63510EN/011722Rapid traverse feedrate reduction ratio for overlapping rapid traverse blo. B-63510EN/01 4. DESCRIPTION OF PARAMETERSB-63510EN/01 4.

DESCRIPTION OF PARAMETERSValid data range 1000 to 99999999Set the arc radius corresponding to the max. 4. DESCRIPTION OF PARAMETERS B-63510EN/014. DESCRIPTION OF PARAMETERS B-63510EN/011762Exponential acceleration/deceleration time constant for cutting feed in th.

B-63510EN/01 4. DESCRIPTION OF PARAMETERSparameter, set the maximum machining speed during linear acceleration/ deceleration before interpolation. Set the time. 4. DESCRIPTION OF PARAMETERS B-63510EN/014. DESCRIPTION OF PARAMETERS B-63510EN/011777Minimumspeed for the automatic corner deceleration function (look-ahead co.

B-63510EN/01 4. DESCRIPTION OF PARAMETERSB-63510EN/01 4. DESCRIPTION OF PARAMETERS1781Allowable speed difference for the speed difference-based corner decelerat. 4.

DESCRIPTION OF PARAMETERS B-63510EN/014. DESCRIPTION OF PARAMETERS B-63510EN/011785Parameter for determining an allowable acceleration when the feedrate is s.

B-63510EN/01 4. DESCRIPTION OF PARAMETERS#7#6#5#4#3#2#1#0RBKFFRCVRData type BitCVR When velocity control ready signal VRDY is set ON before position control r. 4. DESCRIPTION OF PARAMETERS B-63510EN/01CTS The servo motor-based speed control function is:0: Not used1: UsedDPS When servo motor-based speed control is app. B-63510EN/01 4.

DESCRIPTION OF PARAMETERSB-63510EN/01 4. DESCRIPTION OF PARAMETERS#7#6#5#4#3#2#1#0APCxAPZxOPTxData type Bit axisOPTx Position detector0: A se. 4. DESCRIPTION OF PARAMETERS B-63510EN/01NOTEWhen the flexble feed gear is used, do not use these parameters.

Set the numerator and denominator of DMR toan appr. B-63510EN/01 4. DESCRIPTION OF PARAMETERS(1) T seriesLeast input incrementLeastcommandincrementIS-BMillimetermachineMillimeterinput0.001 mm (diameter specificat. 4. DESCRIPTION OF PARAMETERS B-63510EN/01Set the magnification ratios of CMR and DMR so that the weight of positive inputs to the error counter equals that of n. B-63510EN/01 4. DESCRIPTION OF PARAMETERSThe relationship between the positioning deviation (the number of pulses counted by the error counter) and the feedrate.

4. DESCRIPTION OF PARAMETERS B-63510EN/014. DESCRIPTION OF PARAMETERS B-63510EN/011830Axis-by-axis positional deviation limit at servo-off timeData type 2-wor. B-63510EN/01 4. DESCRIPTION OF PARAMETERS1851Backlash compensating value for each axisData type Word axisUnit of data Detection unit Valid data range -999. 4.

DESCRIPTION OF PARAMETERS B-63510EN/01NOTE1 Jog feed is regarded as cutting feed.2 The backlash compensation depending on a rapid traverse and a cutting feed. B-63510EN/01 4.

DESCRIPTION OF PARAMETERSBy using this parameter, calculate the machine position from the expression below.Machine position = ( M-S- (parameter. 4. DESCRIPTION OF PARAMETERS B-63510EN/014.

DESCRIPTION OF PARAMETERS B-63510EN/011885Maximum allowable value for total travel during torque controlData type. B-63510EN/01 4. DESCRIPTION OF PARAMETERSThe following parameters are not explained in this manual. Refer to FANUC AC SERVO MOTOR a Series PARAMETER MANUAL(B-65. 4. DESCRIPTION OF PARAMETERS B-63510EN/01No.Data typeContents2048Word axisBacklash acceleration2049Word axisMaximum amplitude for dual position feedback2050Word.

B-63510EN/01 4. DESCRIPTION OF PARAMETERSNo.Data typeContents2097Word axisStatic friction compensation stop parameter2098Word axisCurrent phase lead compensatio. 4. DESCRIPTION OF PARAMETERS B-63510EN/01#7#6#5#4#3#2#1#03001MHIRWMData type BitRWM RWD signal indicating that rewinding is in progress0: Output only when th.

B-63510EN/01 4. DESCRIPTION OF PARAMETERS#7#6#5#4#3#2#1#03004OTHBCYBSLBSL The block start interlock signal.BSL and cutting block start interlock signal.CSL ar. 4.

DESCRIPTION OF PARAMETERS B-63510EN/014. DESCRIPTION OF PARAMETERS B-63510EN/013011Acceptable width of M, S, T, and B function completion signal (FIN)Data t. B-63510EN/01 4. DESCRIPTION OF PARAMETERSB-63510EN/01 4.

DESCRIPTION OF PARAMETERS3030Allowable number of digits for the M code3031Allowable number of digits fo. 4. DESCRIPTION OF PARAMETERS B-63510EN/01#7#6#5#4#3#2#1#03100CORPARAMETERS OF MDI, DISPLAY,AND EDITCOR 7-pieces type soft key display0: Monochrome display1: C. B-63510EN/01 4. DESCRIPTION OF PARAMETERSB-63510EN/01 4.

DESCRIPTION OF PARAMETERS#7#6#5#4#3#2#1#03104DACDALDRCDRLPPDMCNData type BitMCN Machine position0: N. 4. DESCRIPTION OF PARAMETERS B-63510EN/01When tool geometry compensation of the T system is to be performed by shifting the coordinate system (with bit 4 (LGT)o. B-63510EN/01 4. DESCRIPTION OF PARAMETERSB-63510EN/01 4.

DESCRIPTION OF PARAMETERS#7 #6#5#4#3#2#1#0OHSSOVOHDSPDGPLOHSSOVOHDGPLData type BitGPL On the program. 4. DESCRIPTION OF PARAMETERS B-63510EN/01#7 #6#5#4#3#2#1#0JSPSLMWCIJSPSLMWCIPCTData type BitPCT On the program check screen, T code displayed0: is a T code s. B-63510EN/01 4.

DESCRIPTION OF PARAMETERS#7#6#5#4#3#2#1#03109RHDIKYDWTData type BitDWT Characters G and W in the display of tool wear/geometry compensation am. 4. DESCRIPTION OF PARAMETERS B-63510EN/01Data type BitSGD Servo waveform0: Not displayed1: DisplayedOMH The external operator message history screen is:0:. B-63510EN/01 4.

DESCRIPTION OF PARAMETERSIPR When the function key is pressed while the program screen is being displayed:0: The screen is changed.1: T. 4. DESCRIPTION OF PARAMETERS B-63510EN/01Example: The current position on the Y-axis is multiplied by ten and displayed.X 1.2345 ^ X 1.2345 Y 1.2345 ^ Y 12.345Z. B-63510EN/01 4.

DESCRIPTION OF PARAMETERSB-63510EN/01 4. DESCRIPTION OF PARAMETERS3122Time interval used to record time data in operation historyData type Wor. 4. DESCRIPTION OF PARAMETERS B-63510EN/014. DESCRIPTION OF PARAMETERS B-63510EN/013134Axis display order on workpiece coordinate system screen and workpiece shi. B-63510EN/01 4. DESCRIPTION OF PARAMETERSNPE With an M02, M30, or M99 block, program registration is assumed to be:0: Completed1: Not completedMIP Program reg.

4. DESCRIPTION OF PARAMETERS B-63510EN/01(5) Program registration(6) Program collation(7) Displaying programsCPD When an NC program is deleted, a confirmation m. B-63510EN/01 4. DESCRIPTION OF PARAMETERSMKP When M02, M30, or EOR(%) is executed during MDI operation, the created MDI program is:0: Erased automatically.1:. 4. DESCRIPTION OF PARAMETERS B-63510EN/014. DESCRIPTION OF PARAMETERS B-63510EN/013211KeywordData type 2-word axisWhen the value set as the password (set in p.

B-63510EN/01 4. DESCRIPTION OF PARAMETERSB-63510EN/01 4. DESCRIPTION OF PARAMETERS#7 #6#5#4#3#2#1#0WPTData type BitWPT The input of the tool wear compensation. 4. DESCRIPTION OF PARAMETERS B-63510EN/01#7 #6#5#4#3#2#1#0GSCGSBFCDDPIABSMABDPIData type BitDPI When a decimal point is omitted in an address that can include.

B-63510EN/01 4. DESCRIPTION OF PARAMETERSB-63510EN/01 4. DESCRIPTION OF PARAMETERS#7 #6#5#4#3#2#1#0G23CLRG91G01G23CLRG91G19G18G01Data type BitG01 Mode entered. 4. DESCRIPTION OF PARAMETERS B-63510EN/01#7 #6#5#4#3#2#1#0M3BEORM02M30SBPPOLM3BEORM02M30SBPPOLNOPData type BitNOP When a program is executed, a block consisti. B-63510EN/01 4.

DESCRIPTION OF PARAMETERSB-63510EN/01 4. DESCRIPTION OF PARAMETERS#7 #6#5#4#3#2#1#0QABQLGDDPCCRG36PPSDWLAUXDWLAUXData type BitAUX The least in.

4. DESCRIPTION OF PARAMETERS B-63510EN/013406#7#6#5#4#3#2#1#0C07C05C04C03C02C01C07C05C04C07C14C11C10C08C15C14C13C11C08C16C20C19C09. B-63510EN/01 4. DESCRIPTION OF PARAMETERSB-63510EN/01 4. DESCRIPTION OF PARAMETERS3411M code preventing buffering 13412M code preventing buffering 23413M code p. 4.

DESCRIPTION OF PARAMETERS B-63510EN/014. DESCRIPTION OF PARAMETERS B-63510EN/01#7 #6#5#4#3#2#1#0NPSCQDCQDAUPData type BitAUP When a command for the second. B-63510EN/01 4. DESCRIPTION OF PARAMETERSB-63510EN/01 4. DESCRIPTION OF PARAMETERS4.13PARAMETERS OF PITCH ERRORCOMPENSATIONNumber of the pitch error compensatio. 4. DESCRIPTION OF PARAMETERS B-63510EN/01Number of the pitch error compensation position at extremely positive position for each axisData type Word axis Unit.

4. DESCRIPTION OF PARAMETERS B-63510EN/01The compensation value is output at the compensationn position No.corresponding to each section between the coordinates. B-63510EN/01 4. DESCRIPTION OF PARAMETERSSet the parameters as follows:ParameterSettingNo.

3620Compensation point number for reference position60No. 3621Compens. 4.

DESCRIPTION OF PARAMETERS B-63510EN/01#7#6#5#4#3#2#1#03700NRFData type BitNRF The first move command (such as G00 and G01) after the serial spindle is swit. B-63510EN/01 4. DESCRIPTION OF PARAMETERSData type BitOR1 Whether the stop-position external-setting type orientation function is used by the first spindle mo.

4. DESCRIPTION OF PARAMETERS B-63510EN/01NOTEThe output of S codes and SF for an S command in constant surface speed control mode (G96), or for an S commandused. B-63510EN/01 4.

DESCRIPTION OF PARAMETERSORM Voltage polarity during spindle orientation0: Positive1: NegativeTCW, CWM Voltage polarity when the spindle speed. 4. DESCRIPTION OF PARAMETERS B-63510EN/014. DESCRIPTION OF PARAMETERS B-63510EN/01#7 #6#5#4#3#2#1#0MRSMSISAMData type BitSAM The sampling frequency to obtain.

4. DESCRIPTION OF PARAMETERS B-63510EN/013735Minimum clamp speed of the spindle motorData type Word Valid data range 0 to 4095Set the minimum clamp speed of. B-63510EN/01 4. DESCRIPTION OF PARAMETERS3741Maximum spindle speed for gear 13742Maximum spindle speed for gear 23743Maximum spindle speed for gear 33744Maximum. 4. DESCRIPTION OF PARAMETERS B-63510EN/013751Spindle motor speed when switching from gear 1 to gear 23752Spindle motor speed when switching from gear 2 to gear. B-63510EN/01 4.

DESCRIPTION OF PARAMETERS3761Spindle speed when switching from gear 1 to gear 2 during tapping3762Spindle speed when switching from gear 2 to ge. 4.

DESCRIPTION OF PARAMETERS B-63510EN/014. DESCRIPTION OF PARAMETERS B-63510EN/013771Minimum spindle speed in constant surface speed control mode (G96)Data ty.

B-63510EN/01 4. DESCRIPTION OF PARAMETERS3802Maximum speed of the second spindleData type WordUnit of data rpmValid data range 0 to 32767Parameter sets th. 4.

DESCRIPTION OF PARAMETERS B-63510EN/01Table 4.14 (a) Parameters for Control of Serial Interface Spindle Cs Contouring Control AxisNo.Data typeDescription3900. B-63510EN/01 4. DESCRIPTION OF PARAMETERSThe loop gain used for Cs contouring control is selected when the mode changes from the spindle mode to the Cscontourin. 4. DESCRIPTION OF PARAMETERS B-63510EN/01Table 4.14 (b) Parameters for Serial Interface Spindle Amplifier (a series, S series) (2/7)No.Data typeDescription4050W.

B-63510EN/01 4. DESCRIPTION OF PARAMETERSTable 4.14 (b) Parameters for Serial Interface Spindle Amplifier (a series, S series) (3/7)No.Data typeDescription4110W. 4. DESCRIPTION OF PARAMETERS B-63510EN/01Table 4.14 (b) Parameters for Serial Interface Spindle Amplifier (a series, S series) (4/7)No.Data typeDescription4170W. B-63510EN/01 4. DESCRIPTION OF PARAMETERSTable 4.14 (b) Parameters for Serial Interface Spindle Amplifier (a series, S series) (5/7)No.Data typeDescription4230W.

4. DESCRIPTION OF PARAMETERS B-63510EN/01Table 4.14 (b) Parameters for Serial Interface Spindle Amplifier (a series, S series) (6/7)No.Data typeDescription4280W. B-63510EN/01 4.

DESCRIPTION OF PARAMETERSTable 4.14 (b) Parameters for Serial Interface Spindle Amplifier (a series, S series) (7/7)No.Data typeDescription4340W. 4. DESCRIPTION OF PARAMETERS B-63510EN/01Notes on parameters of the spindle amplifier with the serial interfaceNOTE1 Among the parameters of the spindle amplifi.

B-63510EN/01 4. DESCRIPTION OF PARAMETERSB-63510EN/01 4.

DESCRIPTION OF PARAMETERS#7#6#5#4#3#2#1#04800ND2ND1When this parameter is set, the power must be turned. 4. DESCRIPTION OF PARAMETERS B-63510EN/014. DESCRIPTION OF PARAMETERS B-63510EN/01#7 #6#5#4#3#2#1#0FLRData type BitFLR When the spindle speed fluctuation dete. B-63510EN/01 4.

DESCRIPTION OF PARAMETERSValid data range 0 to 32767Set the allowable fluctuation speed (Sd) for which no alarm is activated in the spindle sp. 4. DESCRIPTION OF PARAMETERS B-63510EN/01Fig.4.14 (f) Sd and Sm#7 #6#5#4#3#2#1#0IMBESITRVISZIDMIORData type BitIOR Resetting the system in the spindle positio. B-63510EN/01 4. DESCRIPTION OF PARAMETERSNOTEThe extended specification includes the following twoextensions:(1) With the conventional specification, the number.

4. DESCRIPTION OF PARAMETERS B-63510EN/014. DESCRIPTION OF PARAMETERS B-63510EN/014961M code releasing the spindle positioning modeData type Word Unit of dat. B-63510EN/01 4. DESCRIPTION OF PARAMETERSValid data range 1 to 60This parameter sets a basic angular displacement used for half-fixed angle positioning using.

4. DESCRIPTION OF PARAMETERS B-63510EN/01the voltage used in the velocity command. Assign the data obtained from the following equation to the parameters.Loop g. B-63510EN/01 4. DESCRIPTION OF PARAMETERS#7 #6#5#4#3#2#1#0EVOTPHEVRTALOFHTLBTLCData type Bit typeTLC Tool length compensation0: Tool length compensation A or. 4. DESCRIPTION OF PARAMETERS B-63510EN/014.

DESCRIPTION OF PARAMETERS B-63510EN/01#7 #6#5#4#3#2#1#0WNPLWMLGCLGTLWTLGNLD1Data type BitLD1 Offset number of tool. B-63510EN/01 4. DESCRIPTION OF PARAMETERS#7 #6#5#4#3#2#1#0TGCLVCCCNLVKCCNSUVSUPData type BitSUP Start up or cancel in cutter compensation C 0: Type A1: Type. 4. DESCRIPTION OF PARAMETERS B-63510EN/01TS1 When the tool offset measurement value direct input B function is used, touch sensor contact detection is based on:.

B-63510EN/01 4. DESCRIPTION OF PARAMETERSB-63510EN/01 4. DESCRIPTION OF PARAMETERS#7 #6#5#4#3#2#1#0CNCCNIG39CNCCNIData type BitCNI Interference check for cutt. 4.

DESCRIPTION OF PARAMETERS B-63510EN/014. DESCRIPTION OF PARAMETERS B-63510EN/015013Maximum value of tool wear compensationData type 2-word Unit of data.

B-63510EN/01 4. DESCRIPTION OF PARAMETERSB-63510EN/01 4. DESCRIPTION OF PARAMETERS5015Distance (XP) betweeen reference position and X axis + contact surface5016. 4. DESCRIPTION OF PARAMETERS B-63510EN/014.

DESCRIPTION OF PARAMETERS B-63510EN/015020Tool offset number used for the input of tool offset value measured BData. B-63510EN/01 4. DESCRIPTION OF PARAMETERS4.16.1#7 #6#5#4#3#2#1#0M5TILVRTRFXYM5BM5TRD2RD1EXCFXYParameter of canned Cycle for DrillingData type BitFXY The drill.

4. DESCRIPTION OF PARAMETERS B-63510EN/014. DESCRIPTION OF PARAMETERS B-63510EN/01#7 #6#5#4#3#2#1#0RDIRABK0EF16QSRMRCData type BitMRC When a target figure oth. B-63510EN/01 4. DESCRIPTION OF PARAMETERSB-63510EN/01 4. DESCRIPTION OF PARAMETERS#7 #6#5#4#3#2#1#0P15QZASIJData type BitSIJ When the FS10/11 format is used (.

4. DESCRIPTION OF PARAMETERS B-63510EN/014. DESCRIPTION OF PARAMETERS B-63510EN/015113Spindle reverse-rotation M code in drilling canned cycleData type Byte. 4. DESCRIPTION OF PARAMETERS B-63510EN/00Chamfering distance in the thread cutting cycles G76 and G92Parameter of Thread Cutting CycleData type Byte.

B-63510EN/01 4. DESCRIPTION OF PARAMETERSValid data range -99999999 to 99999999This parameter sets the escape in multiple repetitive canned cycle G73 of an X,. 4. DESCRIPTION OF PARAMETERS B-63510EN/014. DESCRIPTION OF PARAMETERS B-63510EN/015142Repetition count of final finishing in multiple repetitive canned cycle G7.

B-63510EN/01 4. DESCRIPTION OF PARAMETERS5164Percentage of the spindle speed to be changed when the tool is retracted after an overload torque signal is receive. 4. DESCRIPTION OF PARAMETERS B-63510EN/015167Percentage of the cutting feedrate to be changed when the tool is retracted without an overload torque signal recei. B-63510EN/01 4. DESCRIPTION OF PARAMETERS5171Number of the macro variable to which the total umber of retractions because of an overload signal is outputData t. 4.

DESCRIPTION OF PARAMETERS B-63510EN/01#7 #6#5#4#3#2#1#0SRSFHDDOVSIGCRGVGRG84FHDPCPDOVSIGCRGVGRG84Data type BitG84 Method for specifying rigid tapping0: An. B-63510EN/01 4. DESCRIPTION OF PARAMETERS#7 #6#5#4#3#2#1#0OV3OVUTDROV3OVUTDRNIZData type BitNIZ Smoothing in rigid tapping is:0: Not performed.1: Performed.

DESCRIPTION OF PARAMETERS B-63510EN/01SPR In rigid tapping, the parameters are:0: Not changed on a spindle-by-spindle basis.1: Changed on a spindle-by-spin. B-63510EN/01 4. DESCRIPTION OF PARAMETERSB-63510EN/01 4. DESCRIPTION OF PARAMETERS5212M code that specifies a rigid tapping modeData type 2-word Unit of data.

4. DESCRIPTION OF PARAMETERS B-63510EN/015214Setting of an allowable rigid tapping synchronization error rangeSetting of an allowable rigid tapping synchronizat. B-63510EN/01 4. DESCRIPTION OF PARAMETERS5221Number of spindle gear teeth (first-stage gear)5222Number of spindle gear teeth (second-stage gear)5223Number of sp. 4. DESCRIPTION OF PARAMETERS B-63510EN/015231Number of position coder gear teeth (first-stage gear)5232Number of position coder gear teeth (second-stage gear)52.

B-63510EN/01 4. DESCRIPTION OF PARAMETERS5241Maximum spindle speed in rigid tapping (first-stage gear)5242Maximum spindle speed in rigid tapping (second-stage g. 4. DESCRIPTION OF PARAMETERS B-63510EN/014. DESCRIPTION OF PARAMETERS B-63510EN/015261Linear acceleration/deceleration time constant for the spindle and tapping. B-63510EN/01 4. DESCRIPTION OF PARAMETERS5271Time constant for the spindle and tapping axis in extraction operation (first-stage gear)5272Time constant for the.

4. DESCRIPTION OF PARAMETERS B-63510EN/015280Position control loop gain for the spindle and tapping axis in rigid tapping (common to all gears)5281Position cont. B-63510EN/01 4. DESCRIPTION OF PARAMETERS5291Spindle loop gain multiplier in the rigid tapping mode (for gear 1)5292Spindle loop gain multiplier in the rigid ta.

4. DESCRIPTION OF PARAMETERS B-63510EN/015300Tapping axis in-position width in rigid tapping5301Spindle in-position width in rigid tappingData type Word Unit. B-63510EN/01 4.

DESCRIPTION OF PARAMETERS5310Positional deviation limit imposed during tapping axis movement in rigid tappingData type WordUnit of data Dete. 4. DESCRIPTION OF PARAMETERS B-63510EN/015312NOTE1 The detection unit is a = La/2048 when the position coderbuilt-in spindle motor uses a position coder of 512. B-63510EN/01 4. DESCRIPTION OF PARAMETERSB-63510EN/01 4.

DESCRIPTION OF PARAMETERS5314Positional deviation limit imposed during tapping axis movement in rigid t. 4. DESCRIPTION OF PARAMETERS B-63510EN/014. DESCRIPTION OF PARAMETERS B-63510EN/015321Spindle backlash in rigid tapping (first-stage gear)Spindle backlash in ri. B-63510EN/01 4. DESCRIPTION OF PARAMETERS5341Position control loop gain for the spindle and tapping axis in rigid tapping using the second spindle (common to al. 4.

DESCRIPTION OF PARAMETERS B-63510EN/015351Positionaldeviation limit imposed during spindle movement in rigid tapping using the second spindleData type Word. B-63510EN/01 4. DESCRIPTION OF PARAMETERS5381Override for rigid tapping retractionData type Byte Unit of data%Valid data range 0 to 200Sets an override v. 4. DESCRIPTION OF PARAMETERS B-63510EN/015400#7#6#5#4#3#2#1#0RINSCRXSCRINData type Bit typeRIN Coordinate rotation angle command (R)0: Specified by an absolu. B-63510EN/01 4.

DESCRIPTION OF PARAMETERS5411Magnificationused when scaling magnification is not specifiedSetting entry is acceptable.Data type 2-wordUnit of. 4. DESCRIPTION OF PARAMETERS B-63510EN/01#7 #6#5#4#3#2#1#0PDIMDLData type BitMDL Specifies whether the G code for single direction positioning (G60) is includ. B-63510EN/01 4. DESCRIPTION OF PARAMETERS5450#7#6#5#4#3#2#1#0AFCData type Bit typeAFC In polar coordinate interpolation mode, automatic override operation and.

Fanuc Oi Programming Manual

4. DESCRIPTION OF PARAMETERS B-63510EN/015463Allowable automatic override percentage in polar coordinate interpolationData type Byte type Unit of data%Val. B-63510EN/01 4. DESCRIPTION OF PARAMETERS5480Number of the axis for controlling the normal directionData type ByteValid data range 1 to the maximum control. 4. DESCRIPTION OF PARAMETERS B-63510EN/014.

DESCRIPTION OF PARAMETERS B-63510EN/015483Limit value of movement that is executed at the normal direction angle of. B-63510EN/01 4. DESCRIPTION OF PARAMETERSData type Unit of data5485Limit imposed on the insertion of a single block for rotation about the normal direction. 4. DESCRIPTION OF PARAMETERS B-63510EN/01#7 #6#5#4#3#2#1#0IDXSIMG90INCABSRELDDPData type Bit typeDDP Selection of decimal-point input method of index table in. B-63510EN/01 4. DESCRIPTION OF PARAMETERS5511Negative-directionrotation command M codeData type Byte Valid data range 0 to 2550: Not use an M code that set.

4. DESCRIPTION OF PARAMETERS B-63510EN/01#7 #6#5#4#3#2#1#0SBMHGOMGOG67SBMHGOV15MGOG67Data type Bit typeG67 If the macro continuous-state call cancel command (. B-63510EN/01 4. DESCRIPTION OF PARAMETERS6001#7#6#5#4#3#2#1#0CLVCCVTCSCROPV5PRTPRT Reading zero when data is output using a DPRINT command0: Outputs a space1:. 4. DESCRIPTION OF PARAMETERS B-63510EN/01MCY Custom macro interrupt0: Not performed during cycle operation1: Performed during cycle operationMUS Interrupt-typ.

B-63510EN/01 4. DESCRIPTION OF PARAMETERS#7 #6#5#4#3#2#1#06010.7.6.5.4.3.2.1.06011=7=6=5=4=3=2=1=06012#7#6#5#4#3#2#1#0601376543210601476543210D. 4.

DESCRIPTION OF PARAMETERS B-63510EN/014. DESCRIPTION OF PARAMETERS B-63510EN/016050G code that calls the custom macro of program number 90106051G code that c.

B-63510EN/01 4. DESCRIPTION OF PARAMETERSB-63510EN/01 4.

DESCRIPTION OF PARAMETERS6080M code that calls the custom macro of program number 90206081M code that c. 4.

DESCRIPTION OF PARAMETERS B-63510EN/016101First variable number displayed on pattern data screen 16102First variable number displayed on pattern data screen. B-63510EN/01 4. DESCRIPTION OF PARAMETERS#7 #6#5#4#3#2#1#0SKFSREHSSMITSK0GSKSKFSREHSSSK0Data type Bit typeGSK In skip cutting (G31), the skip signal SKIPP (bi. 4. DESCRIPTION OF PARAMETERS B-63510EN/014. DESCRIPTION OF PARAMETERS B-63510EN/01NOTEThere are two types of compensation: Types A and B. With the skip function.

B-63510EN/01 4. DESCRIPTION OF PARAMETERSB-63510EN/01 4.

DESCRIPTION OF PARAMETERSSKIPP (bit 6 of G006) and +MIT1 to -MIT2 (bits 2 to 5 of X1004) are enabled on. 4.

DESCRIPTION OF PARAMETERS B-63510EN/014.26#7#6#5#4#3#2#1#06240AE0PARAMETERS OF AUTOMATIC TOOLCOMPENSATION(T SERIES) ANDAUTOMATIC TOOLLENGTHCOMPENSATION(M SER. B-63510EN/01 4. DESCRIPTION OF PARAMETERSB-63510EN/01 4.

DESCRIPTION OF PARAMETERS6254£ value on X axis during automatic tool compensation£ value during autom. 4. DESCRIPTION OF PARAMETERS B-63510EN/01#7 #6#5#4#3#2#1#0NZMDPAData type BitDPA Current position display on the graphic display screen0: Displays the actual.

B-63510EN/01 4. DESCRIPTION OF PARAMETERS4.29#7#6#5#4#3#2#1#06700PCMPARAMETERS OF DISPLAYINGOPERATION TIMEAND NUMBER OFPARTSData type BitPCM M code that count. 4. DESCRIPTION OF PARAMETERS B-63510EN/016712Total number of machined partsSetting entry is acceptable.Data type 2-word Unit of data One pieceValid data ra.

B-63510EN/01 4. DESCRIPTION OF PARAMETERSB-63510EN/01 4.

DESCRIPTION OF PARAMETERS6752Operation time (integrated value of time during automatic operation) IISet. 4. DESCRIPTION OF PARAMETERS B-63510EN/01Setting entry is acceptable. 2-wordOne ms0 to 60000Operation time (integrated value of one automatic operation time) I6. B-63510EN/01 4. DESCRIPTION OF PARAMETERS#7 #6#5#4#3#2#1#0SNGGRSSIGLTMGS2GS1M6TIGISNGGRSSIGLTMGS2GS1Data type GS1, GS2BitThis parameter sets the combination o. 4.

DESCRIPTION OF PARAMETERS B-63510EN/014. DESCRIPTION OF PARAMETERS B-63510EN/01#7 #6#5#4#3#2#1#0EXGE1STSMM6EEXTE1SEMDLFVCUTData type BitCUT The tool life m. B-63510EN/01 4. DESCRIPTION OF PARAMETERS#7#6#5#4#3#2#1#06802T99Data type BitT99 If a tool group whose life has expired is found to exist when M99 is executed.

4. DESCRIPTION OF PARAMETERS B-63510EN/016810Tool life management ignored numberData type Word Valid data range 0 to 9999This parameter sets the tool life m. B-63510EN/01 4. DESCRIPTION OF PARAMETERSB-63510EN/01 4.

DESCRIPTION OF PARAMETERS6845Remaining tool life (use duration)Data type 2-word Unit of data Minute. 4. DESCRIPTION OF PARAMETERS B-63510EN/01#7#6#5#4#3#2#1#06901IGPData type Bit typeIGP During follow-up for the absolute position detector, position switch sig. B-63510EN/01 4. DESCRIPTION OF PARAMETERSB-63510EN/01 4. DESCRIPTION OF PARAMETERS6930Maximum operation range of the first position switch6931Maximum operation. 4.

DESCRIPTION OF PARAMETERS B-63510EN/014.327001#7#6#5#4#3#2#1#0MINPARAMETERS OF MANUAL OPERATIONAND AUTOMATICOPERATIONData type BitMIN The manual interventi. B-63510EN/01 4. DESCRIPTION OF PARAMETERS#7#6#5#4#3#2#1#07100HPFHCLIHDTHDJHDPARAMETERS OF MANUAL HANDLEFEED AND HANDLEINTERRUPTIONData type BitJHD Manual hand. 4. DESCRIPTION OF PARAMETERS B-63510EN/017110Number of manual pulse generators usedData type Byte Valid data range 1, 2, or 3This parameter sets the number. B-63510EN/01 4. DESCRIPTION OF PARAMETERSB-63510EN/01 4.

DESCRIPTION OF PARAMETERS7117Allowable number of pulses that can be accumulated during manual handle fe. 4. DESCRIPTION OF PARAMETERS B-63510EN/014.347181First withdrawal distance in reference position setting with mechanical stopperPARAMETERS OF REFERENCEPOSITION. B-63510EN/01 4. DESCRIPTION OF PARAMETERS7183First butting feedrate in reference position setting with mechanical stopperData type Word axis Unit of data and. 4. DESCRIPTION OF PARAMETERS B-63510EN/01#7#6#5#4#3#2#1#07200OP7OP6OP5OP4OP3OP2OP1Data type BitOP1 Mode selection on software operator’s panel0: Not perfor.

B-63510EN/01 4. DESCRIPTION OF PARAMETERS7210Job-movementaxis and its direction on software operator's panel Tj7211Job-movement axis and its direction on softw. 4. DESCRIPTION OF PARAMETERS B-63510EN/01Data type Byte7220Name of general-purpose switch on software operator's panel111lll7283Name of general-purpose switch.

B-63510EN/01 4. DESCRIPTION OF PARAMETERSB-63510EN/01 4. DESCRIPTION OF PARAMETERS7284Name of general-purpose switch on software operator's panel (extended)7285. 4. DESCRIPTION OF PARAMETERS B-63510EN/01#7#6#5#4#3#2#1#07300MOUMOAData type BitMOA In program restart operation, before movement to a machining restart point. 4.

Fanuc Parameter Manuals

DESCRIPTION OF PARAMETERS B-63510EN/014.38#7#6#5#4#3#2#1#08001SKEAUXNCCRDEOVEMLEPARAMETERS OF AXIS CONTROL BYPMCData type BitMLE Whether all axis machine l. B-63510EN/01 4. DESCRIPTION OF PARAMETERSB-63510EN/01 4. DESCRIPTION OF PARAMETERS#7#6#5#4#3#2#1#08002FR2FR1PF2PF1F10SUEDWERPDData type BitRPD Rapid traverse. 4. DESCRIPTION OF PARAMETERS B-63510EN/014.

DESCRIPTION OF PARAMETERS B-63510EN/01#7 #6#5#4#3#2#1#0NDINCIDSLJFMNMTCMVNCIDSLG8RG8CJFMNMTCMVCMV When a move comman. B-63510EN/01 4.

DESCRIPTION OF PARAMETERS#7 #6#5#4#3#2#1#0MFDDRRR10CDIEDCMFDDRRR10EDCData type BitEDC In PMC-based axis control, an external deceleration sign. 4. DESCRIPTION OF PARAMETERS B-63510EN/01Data type Word Unit of dataUpper-limitrate of feed per revolution during PMC axis control8022Increment systemUnit d. B-63510EN/01 4. DESCRIPTION OF PARAMETERS8130Total number of controlled axesData type Byte Valid data range 2 to 4Specify the total number of controlled axe. 4. DESCRIPTION OF PARAMETERS B-63510EN/014.

DESCRIPTION OF PARAMETERS B-63510EN/01#7 #6#5#4#3#2#1#0BCDYOFTLFSCLSPKIXCBCDTLFData type BitTLF Specifies whether. B-63510EN/01 4. DESCRIPTION OF PARAMETERSB-63510EN/01 4. DESCRIPTION OF PARAMETERS#7 #6#5#4#3#2#1#0SYCMSPSCSAXCSSCSYCSCSSSCData type BitSSC Specifies whether. 4. DESCRIPTION OF PARAMETERS B-63510EN/01#7 #6#5#4#3#2#1#0SOFData type BitSOF The synchronization funciton in simple synchronous control is:0: Not used.1: U.

B-63510EN/01 4. DESCRIPTION OF PARAMETERSExample: Simple synchronous control is exercised:When using the first axis (X-axis) as the master axis, and the third a. 4. DESCRIPTION OF PARAMETERS B-63510EN/014. DESCRIPTION OF PARAMETERS B-63510EN/018314Maximum error in synchronization error checkData type Word axis Unit of.

B-63510EN/01 4. DESCRIPTION OF PARAMETERS8341Program number subject to check terminationData type Word Valid data range 0 to 9999This parameter sets the pro. 4. DESCRIPTION OF PARAMETERS B-63510EN/01#7#6#5#4#3#2#1#08701WPRData type BitWPR The function that allows parameters that are rewritten using the PMC window t. B-63510EN/01 4. DESCRIPTION OF PARAMETERS#7#6#5#4#3#2#1#08901FANData type BitFAN A fan motor error is:0: Detected.

(When the fan motor error is detected, an. APPENDIX. B-63510EN/01 APPENDIXA.

CHARACTER CODE LISTCharacterCodeCommentCharacterCodeCommentA060D0632SpaceF070!033Exclamation markG071”03. B-63510EN/01 Index Character Code List, 231 Description of Parameters, 1 Displaying Parameters, 1 Inputting and Outputting Parameters Through the Reader/P.

Revision RecordFANUC Series 0i - MODEL A PARAMETER MANUAL (B-63510EN01Jun., 2000EditionDateContentsEditionDateContents.

Fanuc 0i parameter manual CNC milling machine. 1. PARAMETER MANUAL B-64310EN/02 FANUC Series 0+-MODEL D FANUC Series 0+ Mate-MODEL D. No part of this manual may be reproduced in any form. All specifications and designs are subject to change without notice. The products in this manual are controlled based on Japan’s “Foreign Exchange and Foreign Trade Law”. The export from Japan may be subject to an export license by the government of Japan.

Further, re-export to another country may be subject to the license of the government of the country from where the product is re-exported. Furthermore, the product may also be controlled by re-export regulations of the United States government. Should you wish to export or re-export these products, please contact FANUC for advice. In this manual we have tried as much as possible to describe all the various matters. However, we cannot describe all the matters which must not be done, or which cannot be done, because there are so many possibilities. Therefore, matters which are not especially described as possible in this manual should be regarded as ”impossible”. B-64310EN/02 DEFINITION OF WARNING, CAUTION, AND NOTE s-1 DEFINITION OF WARNING, CAUTION, AND NOTE This manual includes safety precautions for protecting the user and preventing damage to the machine.

Precautions are classified into Warning and Caution according to their bearing on safety. Also, supplementary information is described as a Note. Read the Warning, Caution, and Note thoroughly before attempting to use the machine. WARNING Applied when there is a danger of the user being injured or when there is a danger of both the user being injured and the equipment being damaged if the approved procedure is not observed. CAUTION Applied when there is a danger of the equipment being damaged, if the approved procedure is not observed. NOTE The Note is used to indicate supplementary information other than Warning and Caution.

Read this manual carefully, and store it in a safe place. B-64310EN/02 PREFACE p-1 PREFACE Applicable models This manual describes the following models that are 'Nano CNC'.

'Nano CNC system' which realizes high precision machining can be constructed by combining these models and high speed, high precision servo controls. In the text, the abbreviations may be used in addition to Model name indicated below. Model name Abbreviation FANUC Series 0i -TD 0i -TD FANUC Series 0i -MD 0i -MD Series 0i -D 0i -D FANUC Series 0i Mate -TD 0i Mate -TD FANUC Series 0i Mate -MD 0i Mate -MD Series 0i Mate -D 0i Mate -D NOTE 1 For an explanatory purpose, the following descriptions may be used according to the types of path control used: - T series: 0i -TD / 0i Mate -TD - M series: 0i -MD / 0i Mate -MD 2 Some functions described in this manual may not be applied to some products. For details, refer to the DESCRIPTIONS (B-64302EN). 3 The 0i -D / 0i Mate -D requires setting of parameters to enable part of basic functions. For the parameters to be set, see Section 4.51, 'PARAMETERS OF 0i -D / 0i Mate -D BASIC FUNCTIONS'.

Related manuals of Series 0i -D,Series 0i Mate -D The following table lists the manuals related to Series 0i -D,Series 0i Mate -D. This manual is indicated by an asterisk(.).