Office Manager Standard Operating Procedures Manual

- Examples Of Standard Operating Procedures

- Office Manager Standard Operating Procedures Manual For Construction Company

Whether you’re starting a business or trying to improve an existing one, you have to understand how things are going to get done. What tasks do you need to do? Who needs to do them? What are the best ways to approach these tasks? Working out how these questions can be answered is the first step toward systemizing your business. The creation of and will define the way in which your day to day activities function.

One popular approach to this is the creation of. The simple definition provided by IBM for standard operating procedures is: a set of instructions that describes all the relevant steps and activities of a process or procedure. But how do we create these SOPs? What we need are standard operating procedures for creating standard operating procedures. And that’s what we’re going to give you. We’ll look at:. How to create a set of standard operating procedures.

Some advanced techniques for improving your SOPs. Why is a useful tool for both mapping and following your standard operating procedures Let’s jump straight into the action with easy steps you can immediately employ. Cessna 172m service manual.

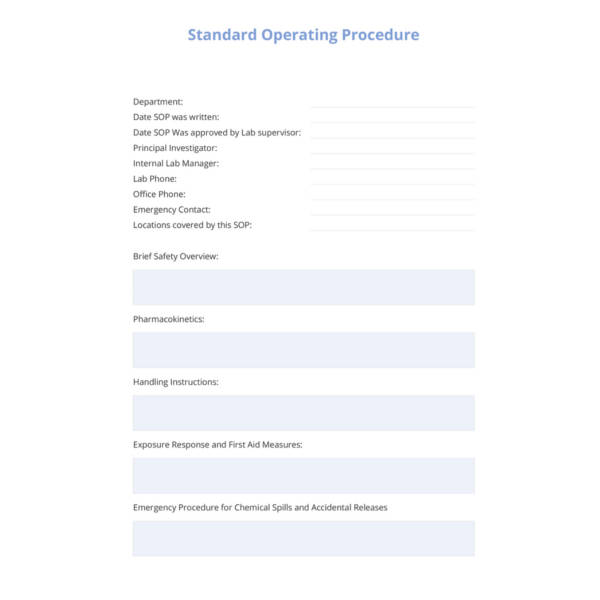

Writing standard operating procedures: a quick how-to guide Step 1: Understand how you are going to present your SOPs There are a number of formats you can choose from when defining how you’ll structure and present your standard operating procedures. The international standard you probably use if you work in a large company is, or some variant of that. ISO-9000 As we go forward with the article, we’ll be keeping things broadly in line with ISO-9000, but we’ll also build off that foundation. A solopreneur might want something a little different, and as good as the ISO method is for SOPs, it has limitations in regards to how actionable it is. We’ll look to improve on that with the use of tools and tech! For anyone who wants to stick as closely as possible to the ISO-9000 structure, I’ve built this structured template below which you can start using right now. This template is designed to adhere to the ISO-9001:2015 Quality Mini-Manual standards.

If you export this template, it will be structured with a title at the top followed by the steps on the left as a contents page. Then each section will be presented individually in full. The image below shows broadly how standard operating procedure documentation is presented. Using Process Street to help you establish SOPs in line with ISO-9000 allows you to also follow those procedures in an way. Two birds, one business process management system. Which format you choose to work with will be dependent on a number of factors. If you work for a large multi-national you’ll need to have standard operating procedures which adhere to the company’s internal policies and standardizations.

If you’re a solopreneur, you may want to have a much simpler layout of your SOPs for your own reference. There are three main approaches to take: Create a simple checklist You can write a simple checklist which outlines the different tasks involved and looks more like a to-do list than a report. This kind of approach has benefits for the solopreneur, or small teams, who don’t require detailed instructions. The advantage of this approach is that it offers a very quick option and allows people to create standard operating procedures as and when they perform new tasks – rapidly noting down the steps they took for future reference. This flexibility can aid startups who are trying new things on a regular basis. The disadvantage of this approach is that the lack of detail results in difficulties when trying to analyze the process.

If the detail is not recorded then optimization and improvement are harder to attain. Create a complex linear checklist It doesn’t have to be too complicated, but this should be like a beefed up version of the above.

This checklist should record as much detail in the process as possible. You can consider whether a single task requires a sub-checklist of further tasks to spell it out.

You can understand how you’re going to document workflows; when do tasks involve multiple people and how do they fit in together? Including detail means you have more variables to iterate when you come to optimizing the process. This approach is the one favored by us. Our goal is to have processes so watertight that anyone could take over the task and be able to complete it. This was one of our methods for improving our customer support process. When we hired new members of staff, we gave them this checklist with detailed instructions and explanations and gave them level 1 support in their first week. If they found something difficult, or couldn’t understand it, then there was a problem in the process.

This system built optimization into the execution of the process. It wouldn’t have been possible without having a detailed process to begin with. Map out a process flow diagram A flow diagram is a useful means of visualizing your standard operating procedures and understanding how the constituent parts come together to form a coherent whole. Flow diagrams are, in general, less actionable than a linear structured checklist. However, flow diagrams are extremely useful for communication of processes.

A process flow chart will help you explain your process structures to others while also easing the analysis of a process when you come to iterate and improve. For the purpose of this article, I’m going to be discussing the methods to construct a detailed checklist.

This approach results in well-documented processes while also providing highly actionable instructions. Step 2: Gather the relevant stakeholders We’re strong believers in the power of collaborative creation.

If you’re going to be creating for particular tasks, processes, or workflows, then you should probably contact the people who will be, or are already, responsible for those duties. If you’re a manager and have a team of people working each day on a set of tasks, you’ll want to understand the thoughts of your team in regards to best practices.

After all, these are the people you pay to perform these tasks day in day out. Teamwork is vital for any business. Building processes collaboratively not only brings in more expertise and scrutiny, it also provides a sense of ownership over the process to the people who are following it. By working in this manner, the process feels like less of a diktat and more of an agreement.

Step 3: Work out your purpose What are you looking to achieve as you build these standard operating procedures? Are they brand new? In which case, you’re trying to create systems which function. But you also want them to function well, and you need to make sure the priorities within the process are aligned with the priorities within the business. If you’re looking to produce standard operating procedures which cover existing and, then you have a few more points to consider.

What are your pain points? Where are your existing processes letting you down and what can you do to change that? Maybe you don’t know – and this is why you’re documenting; to investigate. Or, more likely, you’ve recognized that the current system is too slow or the final product is not consistently of a high quality. You have a pain point which you wish to target. We spoke to one of our Process Street users who runs a chain of healthy restaurants across Canada called about how they approached.

He told us a story of one of the clearest process related pain points he had experienced. Payroll kept going wrong. There always ended up being mistakes.

To tackle this, he created a detailed process breakdown of the tasks involved and made sure that it was held to every time. He responded to the poor quality with clarity and detail – making the process longer if necessary. With a possible hint of humor in his voice, he told us: “ We have eliminated 100% of mistakes“. Step 4: Determine the structure of your SOP If you’re in a large company, the standard operating procedures will take the form of a quite formal report.

The typical approach to a report like this is to include a cover page with the title and all the relevant reference details, followed by a list of chapters, before embarking on the processes themselves. If you work in a or a small company, this level of formality isn’t always kept to. Nonetheless, this approach is founded on common sense structure and it’s a good idea to follow it. Within the Process Street platform, we’ve constructed our export features to deal with this and to present the online processes report-style when exported to. This way, we’re able to operate by our processes with the flexibility of the platform while also giving clients who need it the ability to save processes as PDFs for reference purposes in line with ISO-9000.

Step 5: Prepare the scope of the procedure If you’re forming a set of standard operating procedures for a particular aspect of a content marketing team’s work, you should be focusing on them and their needs. Learn where to draw the line to stop you wandering off into other teams or departments. You can discuss how a workflow may span, but you should know from the beginning whether that is the case or not. Define the limits of your investigation or you’ll end up with mission creep. What are you dealing with?

What action initiates the process you’re working on? What action finishes the process you’re working on? Define your scope. Step 6: Use a consistent style Again, if you’re working for a large multinational, everything you do is going to be more formal than Gary and his startup of one.

Whether you’re going to be using sharp formal language or not depends on the professional setting you’re in. However, we do have some tips and tricks built up over time which are broad suggestions applicable in all scenarios. Start with action commands. Always use a verb at the beginning of a statement for a task. This kind of language makes it clear what you have to do and it packs a punch. Be concise.

Don’t waffle in a SOPs report. Be clear and convey the important information only.

Talk to the air rather than the reader. Make it scannable. Normally, that might be considered blog writing advice, but when listing detailed instructions for a particular task within the workflow, put the actionable sections first and follow with the explanation.

Don’t make readers sift through paragraphs of text every time they want to follow the SOPs. Step 7: Use correct notation, if applicable If you’re at a large company, they may have a system which you have to learn and follow. Some of these systems are a little idiosyncratic and tied to the company.

Most, however, will use a standardized form of notation like. No one says you have to use BPMN or any variation thereof, but systems like that are useful in you’re in a corporate environment or one where you have to work closely with people from other companies. Think of tools like BPMN as universal languages, the Esperanto of. You may be able to employ some of these mapping techniques and methodologies later in the process if they’re visual rather than textual. Step 8: Work out all the necessary steps of the process Now it’s time to put in the hard graft. Collaboratively walk through the process from start to finish noting down every step which must be taken along the way. Allow for input and discussion across the team, and record down any further steps which are suggested.

Then, once you have the spine of the process, go through and look at each task you have recorded. Are there sub-tasks which can be added to that task to further explain either how it is done, or by recommending productive ways to do it?

If so, include the sub-tasks too. This extra detail is important to make an easy to follow process. Within Process Street, you can create sub-checklists in tasks to tackle this need. Provide a simple way to make processes appear straightforward while also adding actionable detail. Step 9: Try to assess potential problems in the process Once you have your process on paper, it’s time to think about whether things can go wrong. And if they can go wrong, where would that failure likely happen?

If you’re using your standard operating procedures to govern a manufacturing process, which can be accounted for easily by numbers, then you can run the calculations. Maybe your process results in high output in terms of production but puts strain on distribution? You know your business better than I, you can make those assessments. We noticed in our that in-depth articles created a degree of risk. If the work was being finished too close to the deadline, then there was always the possibility that the deadline would be missed.

Examples Of Standard Operating Procedures

More likely, the deadline won’t be missed, but less editing and iteration can occur on an article – which risks a reduction in quality. We tackled this by simply attaching earlier submission deadlines to articles.

This way, the whole team can work one or two weeks ahead of schedule and risk can be minimized. Sometimes the most effective changes to a process can be some of the most simple.

Step 10: Determine metrics against which the SOPs can be judged To know whether your process is performing well or poorly, you need to have metrics to judge it against. It is not good enough to assume the process is simply working.

We need to understand how it is performing so that we can optimize it. If you’re constructing SOPs for a you may be looking at metrics like:. How many leads are generated per week?. What is the average length of a sales call?. How many conversions are we getting each week?. What are our sales totals per week? Once you’ve established what questions you’re asking, you can act upon them.

How were you performing against these questions previously? Has the new process improved these numbers? What long-term targets do you want to set for staff to work towards? Once you have the metrics defined, you can assess the performance of the process, and assess the performance in relation to the company’s broader goals. Step 11: Test the process It’s time for the moment of truth. Now that you’ve defined your standard operating procedures, you can put them into practice. How you implement them is up to you and it depends on the resources you have available.

Maybe, to continue with the sales example given above, you have a sales team of 10 and you set 3 people on the new process. This controlled test of the new potential SOPs will allow you to gather comparative data in real time on the performance of the two models – existing and new. If you’re happy that your new is better than the previous one and you want to implement it straight away so that you can start iterating, then you can test other areas. For example, we have an internal, I’ve previously mentioned, which we run every time we deal with a customer question.

This process was forged over time and now functions smoothly and easily. One of the methods we used to test how easy it was to follow was to put new hires in the company on level 1 support in their first week. They were left with customers and a process.

This was a baptism of fire – not just for the hire, but for the process. If the process was good enough, the job would be done well regardless of experience. Step 12: Send the process to superiors If you’re running your own company, then you may not have any superiors to send your SOPs to.

Office Manager Standard Operating Procedures Manual For Construction Company

Really, it’s more about having someone with experience look over the standard operating procedures to give you feedback. Someone who was not involved in the collaborative creation process, and can look at the flows with fresh eyes. If you’re a small business, this could be an investor, someone from your network, or even a valued customer! If you’re working in a large company, this will likely be a mandated part of your SOPs writing process in order to seek approval on the work. If so, make sure to send the results of any testing you have undertaken along with the draft SOPs. Step 13: Clarify the method of optimizing the process Optimizing the process over time is a crucial step of creating it in the first place.

I’m under the belief that the process should be thought of as a living document. No process is ever perfect, and nor can it be. The processes can, however, be as good as we can possibly make them. We have a simple checklist here which can help direct the process for a process: Optimizing a process involves a number of the steps we have already covered. It is important to remember that we work as a team and the processes’ strengths and weaknesses might be found by the people who follow them each day.

Stay collaborative in the optimization process. Where you’ll seek to optimize could – and should – be driven by your key metrics. If they are the means by which you’re measuring performance, then they will likely guide you in your pursuit of the perfect process.

One of the key steps to improving the process is to consider integrating other tools and automated components into your workflow. You can check out a few more articles and ebooks related to business process automation here:. – ebook. – ebook Step 14: Run a risk assessment on your process A risk assessment is an important part of finalizing any project.

If you’re a software firm, you’ve probably already covered this in one of the above sections where we look at where things go wrong. However, if you’re in manufacturing, transport, or a range of other industries, the assessment is even more important. Whenever you have actual real human beings doing something under your direction, you’re responsible for making sure they’re not going to be hurt in the process. Don’t overlook safety in favor of speed. Step 15: Consider creating a flow diagram Flow diagrams or workflow maps – or whatever nomenclature you prefer – can be useful in multiple ways:. Visual overviews.

Sometimes it is useful when presenting information to give visual aids. These aids can contextualize information from the beginning, improving the clarity of your more detailed written explanation.

Help employees understand their role. Flow diagrams provide employees with a visual way of understanding what is being asked of them. But that’s not all. Helping make sure that your employees understand their position within a broader whole makes the process work better and improves employee accountability in the workplace, to boot. Step 16: Finalize and implement the SOPs Congratulations!

You’ve completed your new standard operating procedures. If you’ve followed the process from beginning to end, your SOPs are essentially guaranteed to improve performance. They should have been tested, they have optimization strategies built in, and you’ve made sure they’re safe. More than this, by using Process Street to implement your SOPs into daily business practices in a way which is both easy to use and trackable, you are putting provisions in place to tackle any hidden or any which may have been slowing the company down. I promised you a thrilling guide to SOPs. I’m pretty sure I’ve delivered. Has this guide been useful for you?

How do you approach standard operating procedures in your business? Thank you for all of the great information! I know I need to create SOPs for all of the tasks in my practice but it was difficult to find the time to even read this blog let alone create the SOPs. And I can guarantee you my staff will not read this whole thing. One thing that I will say, I have definitely taken away from this article is to make it a collaborative effort. What I do is have each of my team members to write a staff training on one of the tasks in their job description or one of our office’s “pain points”.

This helps to clarify to everyone how this particular task should be run in the office. By doing this, I’m hoping to take your 16 Essential steps, apply them to the individual staff trainings and eventually have SOPs for every job in our office. Again, not an easy feat but your great article I do believe will definitely help. Thanks again for the info!

The Standard Operating Procedures Manual (SOPM) provides our schools and personnel with the procedural framework necessary to develop supportive, inclusive education programs citywide, based on each student’s individual needs. We understand that regulations and DOE structures may change over time, and we are always working to refine our practices and guidance. Therefore this will be a living document, updated continually to remain current and comprehensive at all times. It is meant to be viewed online rather than printed. Please see New and Notable for a summary of the most recent changes.